Description

Duct heaters for air heating systems, supplementary heating in heat regeneration systems in buildings or in connection with air duct systems.

We design and manufacture all duct heaters according to customer specifications.

Duct heaters for air heating systems, supplementary heating in heat regeneration systems in buildings or in connection with air duct systems.

Jingang rectangular duct heater are supplied in customized sizes and with an output of up to 200KW. They are used to heat up the inlet air in duct systems, in centralized air handling units and for various industrial processes. Our flexible production enable us to precisely adapt the duct heaters to the intended application. This may concern heaters for air handling units, industrial processes or very harsh environments. This may require electrical insulation, stainless materials, large power requirements and high temperatures.

Our duct heaters consist of finned tubular heating elements that are either flanged or inserted in the duct. Air duct heaters are primarily used in air flowing ventilation systems and comfort heating applications.

Jingang designs and configures your electric duct heaters according to your specifications. Our team is dedicated to development of the latest technologies, while striving to meet every customer’s needs by manufacturing quality duct heaters. Our extensive expertise in developing and manufacturing electric duct heaters make our duct heaters, the most easily adaptable solutions for all air-heating applications.

| KW | Power Supply | Duct Size | Min. Air Flow | No of Elements | Model No | Appr. Weight | ||||

| 230V | 415V | CFM | m³/min | Flange | Insert | KG | ||||

| 1Ø | 3Ø | mm | mm | |||||||

| 1 | ✓ | – | 150 | 150 | 50 | 1.4 | 2 | F06x06-01 | I06x06-01 | 7 |

| 2.5 | ✓ | – | 150 | 150 | 150 | 4.2 | 3 | F06x06-025 | I06x06-025 | 7 |

| 7.5 | – | ✓ | 350 | 200 | 390 | 11 | 6 | F14x08-075 | I14x08-075 | 9 |

| 10 | – | ✓ | 350 | 300 | 500 | 14.1 | 6 | F14x12-10 | I14x12-10 | 11 |

| 12.5 | – | ✓ | 400 | 300 | 625 | 17.7 | 6 | F16x12-125 | I16x12-125 | 14 |

| 15 | – | ✓ | 450 | 300 | 750 | 21.2 | 6 | F18x12-15 | I18x12-15 | 14 |

| 17.5 | – | ✓ | 450 | 350 | 875 | 24.8 | 6 | F18x14-175 | I18x14-175 | 16 |

| 20 | – | ✓ | 450 | 400 | 1000 | 28.3 | 6 | F18x16-20 | I18x16-20 | 16 |

| 25 | – | ✓ | 500 | 450 | 1250 | 35.4 | 9 | F20x18-25 | I20x18-25 | 23 |

| 30 | – | ✓ | 600 | 450 | 1500 | 42.4 | 9 | F24x18-30 | I24x18-30 | 25 |

| 35 | – | ✓ | 600 | 550 | 1650 | 46.7 | 9 | F24x22-35 | I24x22-35 | 27 |

| 40 | – | ✓ | 650 | 600 | 2050 | 58 | 12 | F26x24-40 | I26x24-40 | 32 |

| 45 | – | ✓ | 700 | 600 | 2200 | 62.2 | 12 | F26x24-45 | I26x24-45 | 34 |

| 50 | – | ✓ | 700 | 650 | 2500 | 70.7 | 12 | F28x26-50 | I28x26-50 | 36 |

| 60 | – | ✓ | 750 | 750 | 3000 | 84.9 | 15 | F30x30-60 | I30x30-60 | 43 |

| 80 | – | ✓ | 900 | 800 | 4000 | 113.1 | 15 | F36x32-80 | I36x32-80 | 48 |

| 100 | – | ✓ | 1050 | 900 | 5250 | 148.5 | 18 | F42x36-100 | I42x36-100 | 59 |

| 120 | – | ✓ | 1200 | 900 | 6000 | 170 | 18 | F48x36-120 | I48x36-120 | 68 |

Standard Design

The casing is made of Galvanized sheet steel which is corrosion resistant. The heating elements are tubular heating elements made from stainless steel, SUS304. The junction box contains all the terminals required for electrical connection. The casing is available in two different designs. The duct heaters are manufactured with an IP43 degree of protection, but are also available with IP55 or IP65.

The products are customized in terms of size and output.

The heaters are suitable for a maximum outlet temperature of 50 °C, a minimum air velocity of 1.5 m/s and a maximum pressure of 1000 Pa.

The two available heater frame constructions are Flange type and Insert type.

| Finned Tubular

All element consist of Kanthal D heating element (80% Nickel, 20% Chromium), precisely centered in a stainless steel tube which is filled with magnesium oxide. The heater is compacted to maximize heat transfer and dielectric properties of magnesium oxide. A stainless steel fins is helically wound on to the tube to increase its heater transfer surface. |

|

| Overtemperature Protections

Duct heaters have built in primary (automatic) and secondary (manual reset thermal cut-out) overtemperature protection. |

|

| Airflow Interlocks

Air flow switch must be provided to stop the heater if the air flow switch senses low or no airflow. The flow switch continuously monitors the airflow and switches off the heater if the air velocity drops below 1.5 m/s and thus prevents overheating. |

|

| Overcurrent Protections

For heater drawing more than 48 amps, fuses or circuit breaker will be used. |

|

| Disconnection Means

For heater installation/maintenance, a disconnect switch is provided to ensure heater cannot be turn on with the disconnect switch turn off. |

|

Calculating Power(KW) Requirements

The volume of air that goes through the duct heater is heated according to the following formula:

P = Q X 0.36 X Delta T

P= Output in W,

Q=Air flow in m3/h,

Delta T = Temperature increase in Celsius

Ensure a minimum air velocity to prevent over heating of heating element.

The duct heaters are dimensioned by default for a minimum air flow of 1.5 m/s and a maximum operating temperature of 50 °C for the outlet air. The air velocity can be calculated using the following formula:

V=Q/(3600 x A),

V = Air Velocity in m/s,

Q= air flow in m3/h,

A =sectional area of duct heater in (WxH), m2

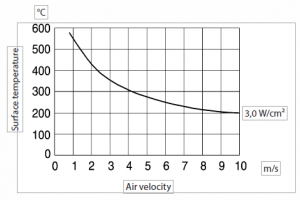

Surface Temperature of Heating Elements

The surface temperature of heating elements is dependent of the air velocity and the heating elements’ surface effect.

The surface effect of the heating elements is approximately 3 W/cm². The table shows the surface temperature of the heating elements when the duct heater’s outlet air temperature is about 20 °C.