Description

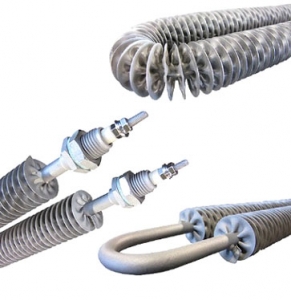

Tubular/finned heater is constructed of highly-compacted magnesium oxide (MgO) based insulation, which conducts heat efficiently from the nickel chromium element wire to the sheath. 24mm wide SUS304 fins are attached to maximize surface contact allowing heat to transfer into the air faster. Lower sheath temperature and element life are maximized by this finned construction.